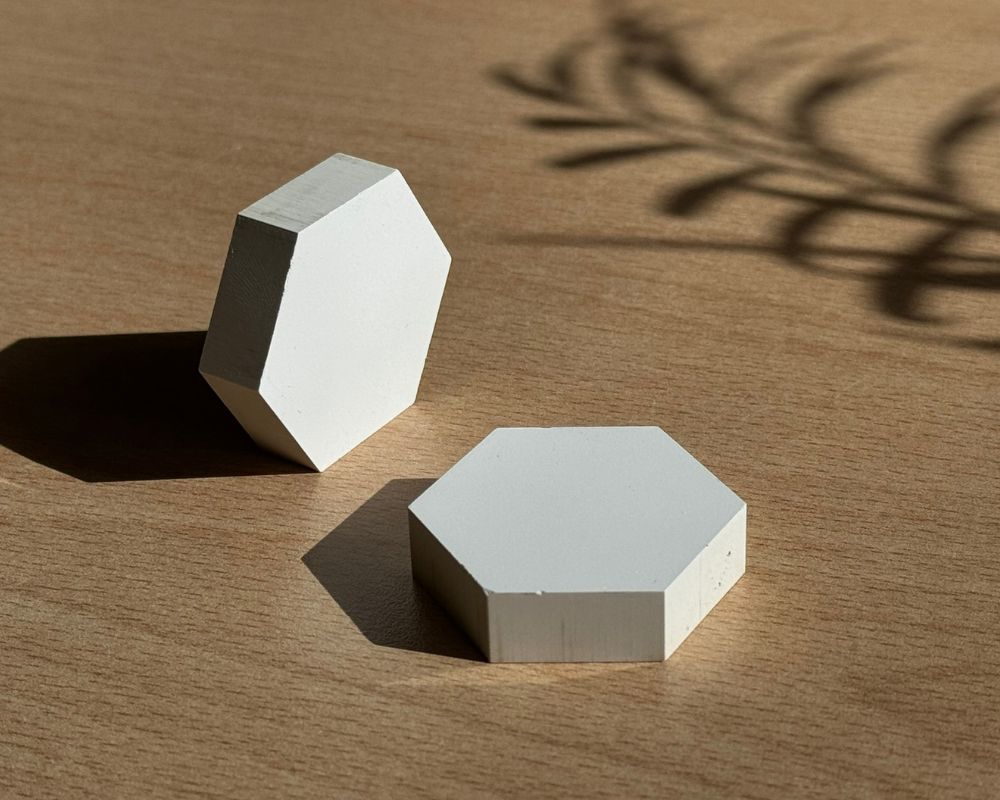

Hexagonal alumina ceramic plate

What is a hexagonal alumina ceramic plate and what are its industrial applications? Hexagonal alumina ceramic plate is an advanced material with crucial applications in modern industry. It is a component made from alumina, an aluminum oxide with exceptional properties that make it ideal for uses that require high resistance to wear and corrosion. This […]

How to Solve Breakage Problems in Ceramic Welding Pins

CERAMIC CENTERING DEVICE AFTER INTENSIVE USE AND TIP BREAKAGE How to Solve Breakage Problems in Ceramic Pins for Resistance Welding Applications in the Automotive Industry Do you have breakage problems in your resistance welding application? In this article you will discover how to solve breakage problems in ceramic or metal pins for resistance welding schedules […]

Comparison of the ceramic centering device with respect to the steel centering device for welding

In comparison, SteelCeram’s solid zirconia centerers represent the strongest and most efficient solution for resistance welding. Its exceptional longevity and resistance guarantee superior performance, optimizing industrial processes and reducing costs in the long term. At SteelCeram SLU, we are proud to offer advanced and customized solutions in ceramic materials. Today, we present a crucial comparison for the resistance welding industry: solid zirconia centering pins versus ceramic-coated metal centering pins and steel centering pins.

Zirconia wire drawing rings

Zirconia Wire Drawing Rings: Optimizing the Performance of your Industrial Wire Drawing Machines In the dynamic world of the copper cabling industry, efficiency and quality are key to staying ahead of the curve. At SteelCeram, we understand the importance of having the best components for your industrial wire drawing machines. That’s why we are excited […]

CERAMIC PISTON – Spare parts for high pressure pumps

Discover why the ceramic piston is the superior choice for your high pressure pump spare parts! Find your ceramic piston for high pressure pumps, increasing the durability of your spare parts. These revolutionary components have completely transformed the performance and efficiency of high-pressure pumps, offering a number of unparalleled advantages over conventional pistons. As an […]

Fluid dispensing solutions made of Alumina.

A fluid dispenser made of advanced ceramics is a device used to measure and control the precise amount of fluids dispensed in various industrial or scientific processes. These dispensers are specifically designed using alumina as the main material in their construction and are primarily used in the pharmaceutical, chemical, cosmetics, and food industries. The advantages […]

Ceramic Filling Pump. Manufacture in alumina.

Ceramic Filling Pump, manufactured in advanced technical ceramics (Alumina 99.7), are a device used to measure and control the precise amount of fluids dispensed in various industrial or scientific processes.

Ceramic pistons for pressure pumps

High pressure pumps are used in a wide range of industrial applications where high pressure or high viscosity flow rates are required. Ceramic pistons are one of the key components in high-performance pumps as they guarantee excellent performance. THE MAIN ADVANTAGES OFFERED BY STEELCERAM CERAMIC PISTONS: High wear resistance High mechanical strength Excellent corrosion […]

Characteristics of ceramic materials

The characteristics of ceramic materials define the behaviour of the material in different situations such as: Resistance to temperature, capacity for electrical insulation and resistance to corrosion. It’s important to have a good knowledge of the characteristics of these materials as these will facilitate what material we need depending on their functionalities. Electrical properties of […]

Mechanical properties of ceramic materials

The mechanical properties of materials are those that define their behaviour when exposed to external forces. There are several types of external forces capable of generating mechanical responses in materials, for example, tensile, compressive and torsional forces. It is important to take into account the forces that will be applied in each industrial process, as […]