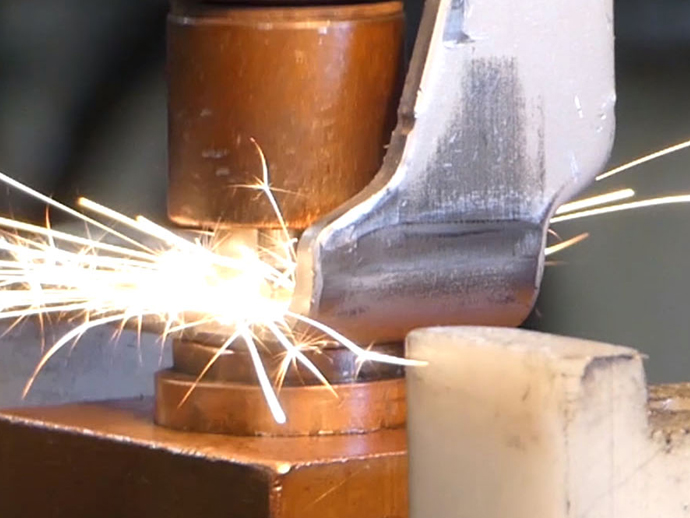

In this article we are going to compare the durability of a ceramic centering pin for resistance welding.

At Steelceram we have specialized in the manufacture of Zirconia ceramic centerers for more than 15 years, and we have a long track record of success stories that generate considerable savings in resistance welding plants. In this article we are going to compare the durability of a ceramic centering device for resistance welding with respect to steel and ceramic-coated centering devices.

Solid Zirconia Centerering Pins

Solid zirconia centerers stand out for their exceptional resistance to high temperatures, wear and corrosion. Their durability far exceeds that of conventional centering inserts, reducing the frequency of replacement and maintenance. They also offer superior dimensional stability, crucial for precise and repetitive welding processes.

Ceramic Coated Metal Centering Pins

Although ceramic coated metal centering pins offer improved wear and corrosion resistance compared to pure steel, their service life is limited due to eventual wear of the coating. Coating adhesion may fail under extreme conditions, compromising centering pin integrity and weld quality.

Steel Centering Pins

Bearings Steel centering bearings are an economical and widely used option. However, their susceptibility to wear and corrosion makes them less durable in high-demand applications. The need for frequent replacement can increase operating costs and downtime.

“The durability of a zirconia ceramic centerer is greatly improved (x40 times more) since its hardness is much higher and it does not wear out or lose tolerance after hundreds of thousands of operations in resistance welding.”

Cost analysis

In the second part of our resistance welding ceramic centering pin comparison, we focus our attention on the maintenance cost savings and operational efficiency that zirconia ceramic centerers can bring to automotive plants compared to steel and steel centerers. with coating.

The use of ceramic centering pins also contributes to increased plant efficiency. By requiring fewer replacements and maintenance, automotive plants can operate more continuously and with fewer unplanned downtimes. This optimizes uptime and improves overall plant productivity.

Durability

One of the most significant factors is durability. A zirconia ceramic centerer has a useful life approximately 15x longer than a coated steel centerer and up to 40x longer than a conventional steel centereing pin. This longevity translates directly into a reduction in replacement frequency, which minimizes production interruptions and reduces long-term operating costs.

It is important to note that in order to maximize the durability and performance of ceramic centering devices, it is crucial that they are correctly calibrated on the machine. Accurate calibration ensures that the centering device operates in optimal conditions and prevents possible breakages.

At SteelCeram, we understand that in some specific cases there may be an increased risk of the tip of the centering pin breaking. For these scenarios, we offer a hybrid solution that combines a metal tip with a ceramic body. This hybrid configuration provides increased strength in critical areas, while maintaining the durability and strength advantages of ceramic in the rest of the centering pin.

By adopting SteelCeram zirconia ceramic centering pins, automotive plants can benefit from increased operational efficiency, lower maintenance costs and an overall improvement in resource management, ensuring a significant and sustainable return on investment.